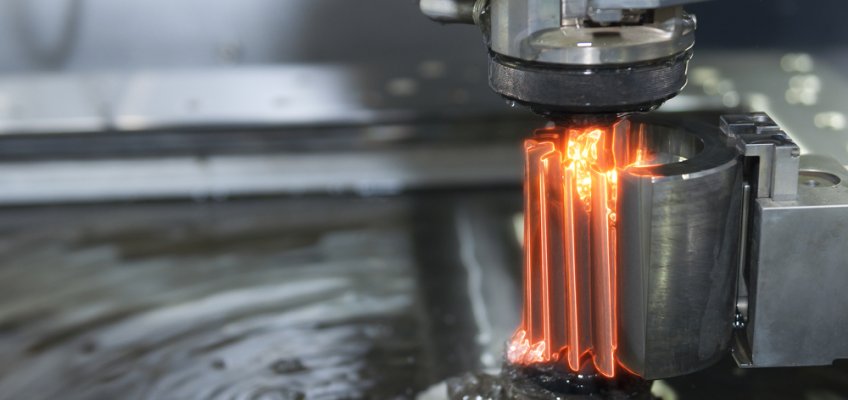

Wire Electrical Discharge Machining (EDM) has become an essential process for industries that demand precision cutting and intricate geometries in hard materials. Whether you run a small job shop or a large manufacturing facility, adding a Wire EDM machine can expand your capabilities and help you deliver high-quality parts with tight tolerances. When the time comes to invest, you will face a critical decision: Should you buy a new or used machine? Understanding the pros and cons of each option will help you choose the best solution for your budget, workload, and long-term goals.

Why Evaluating Both New and Used Machines Makes Sense

Many businesses assume that only new equipment can deliver the accuracy and reliability needed for demanding applications. However, pre-owned machines often provide excellent performance at a significantly lower cost. The right choice depends on factors such as your production volume, available capital, and the types of parts you plan to produce.

Some shops also choose to upgrade their machines with modern consumables like Wire Edm For Sale, which can improve cutting speed and surface finish even on older equipment. This combination of a quality used machine and high-performance consumables is one reason many manufacturers see value in the pre-owned market.

Advantages of Buying a New Wire EDM Machine

Purchasing a new machine comes with several clear benefits:

- Latest Technology: New machines often include advanced features like linear motor drives, adaptive controls, and fully automated wire threading. These technologies can significantly boost productivity.

- Warranty and Support: New equipment typically comes with a comprehensive warranty, ensuring prompt service if something goes wrong.

- Energy Efficiency: Modern machines are designed to use less power and dielectric fluid, reducing operating costs over time.

- Software Compatibility: Newer models usually integrate seamlessly with the latest CAD/CAM systems and remote monitoring tools.

If your work demands cutting-edge performance and you have the budget to support it, a new machine is often the best choice.

Benefits of Buying a Used Wire EDM Machine

Used Wire EDM machines can also be a smart investment, particularly for shops with tighter budgets or those expanding capabilities without taking on significant debt. Here are some advantages:

- Lower Upfront Cost: Pre-owned machines often cost 30–60% less than new models, freeing up capital for other investments.

- Proven Reliability: Many used machines have a long track record of stable performance, especially when they’ve been maintained properly.

- Shorter Lead Times: New machines sometimes involve long delivery schedules, while used machines can be installed much faster.

- Upgradeable Components: You can often retrofit older machines with updated controls, power supplies, and consumables to improve performance.

However, used machines also require careful evaluation to ensure you don’t inherit hidden problems.

What to Consider When Comparing New and Used Equipment

Here is a checklist to guide your decision-making process:

1. Machine Condition

For used machines, inspect:

- Hours of operation

- Maintenance records

- Calibration reports

- The physical condition of guides, power feeds, and tensioning systems

A reputable seller should provide thorough documentation and demonstrate the machine under power.

2. Capability and Size

Confirm that the work envelope, Z-axis travel, and wire diameter range meet your current and future production needs.

3. Accuracy and Surface Finish

Ask for sample parts or run a test cut to verify the machine can achieve your required tolerances and finishes.

4. Software and Controls

Make sure the CNC controls and software are compatible with your design and programming systems. Older controls may need upgrades to remain efficient.

5. Support and Parts Availability

With a new machine, support is usually built in. For used machines, ensure the manufacturer or dealer can still supply parts and service when needed.

6. Financing and Warranties

Compare financing options, warranties, and service contracts. Even used machines sometimes come with limited warranties from reputable resellers.

Budget Considerations

While used equipment has a lower upfront price, remember to include these costs in your budget:

- Installation and rigging

- Training for operators

- Necessary repairs or upgrades

- Consumables and maintenance supplies

Evaluate the total cost of ownership over the next five to ten years, not just the purchase price.

Conclusion

Choosing between new and used Wire EDM machines requires careful consideration of your production requirements, budget, and long-term plans. A new machine delivers the latest technology and worry-free operation, while a quality used machine can be an affordable way to expand capacity. By taking the time to assess each option thoroughly, you can find a Wire EDM solution that helps your shop grow and stay competitive in today’s demanding manufacturing environment.